Blog

Lifting and Handling News and Tips

-

How We Certify Confidence in the Lifting an Manual Handling Equipment We Sell

Lifting and manual handling equipment certification and safety UK businesses can depend on. We supply equipment that is fit for its intended purpose and backed by the correct certification. From chain slings and lifting beams to shackles, crane attachments, and lifting eyes, customers can be certain each item meets compliance standards, remains traceable, and is safe to use. Unlike some...Continue reading -

Dale Lifting and Handling – UK Experts in Lifting Equipment & Custom Solutions Since 1830

At Dale Lifting and Handling, we don’t just supply lifting equipment we deliver engineered solutions shaped by almost two centuries of experience. Established in 1830, we began as traditional chain makers for the Admiralty. Since then, we’ve grown into a leading UK manufacturer and supplier of bespoke lifting and handling equipment. Today, we proudly support British industry and serve clients...Continue reading -

Manual Handling Equipment Helps Retain Experienced Warehouse Workers

In today’s competitive logistics and warehousing landscape, companies are increasingly recognising that one of their most valuable assets is not their inventory or machinery but their workforce. More specifically, the experience and reliability that come with older employees can be vital to operational success. However, retaining these experienced professionals in physically demanding roles such as warehousing requires thoughtful strategy, and...Continue reading -

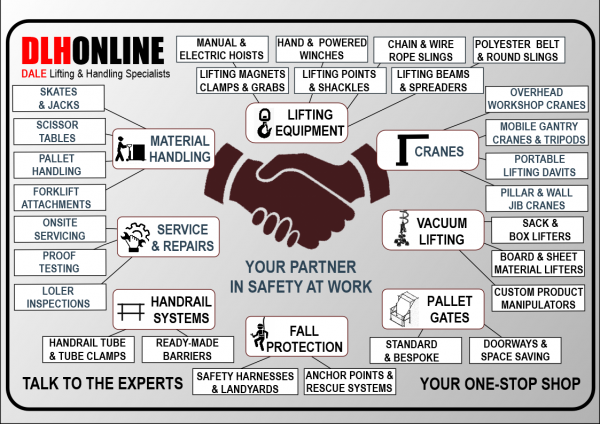

DLHOnline Your Partner in Lifting and handling Safety at Work

dlhonline.co.uk has some great features to explore! Your one-stop shop for lifting and handling equipment Here are a few bullet points highlighting what you can expect: - An easy-to-navigate menu - A wide range of products and services is available Lifting, hoisting and winching Material handling equipment Handrail systems and safety gates Cranes for all industries Vacuum lifting Height safety...Continue reading -

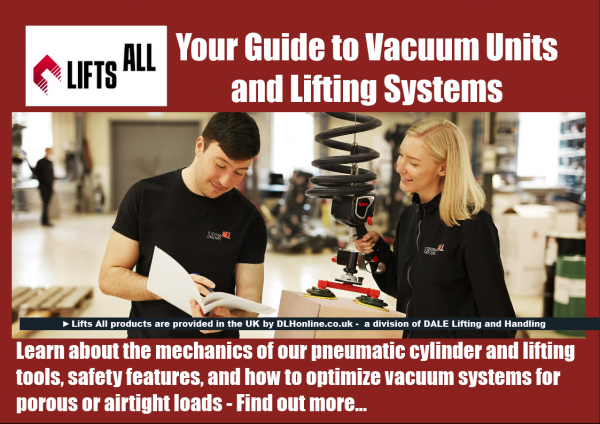

Your Guide to Vacuum Units and Lifting Systems

Precision and safety are crucial when it comes to lifting and handling equipment. This guide from Lifts All outlines essential concepts related to vacuum technology, including absolute pressure and important units like bar and PSI. You will learn about the mechanics of our pneumatic cylinders and lifting tools, the safety features involved, and how to optimize vacuum systems for both...Continue reading -

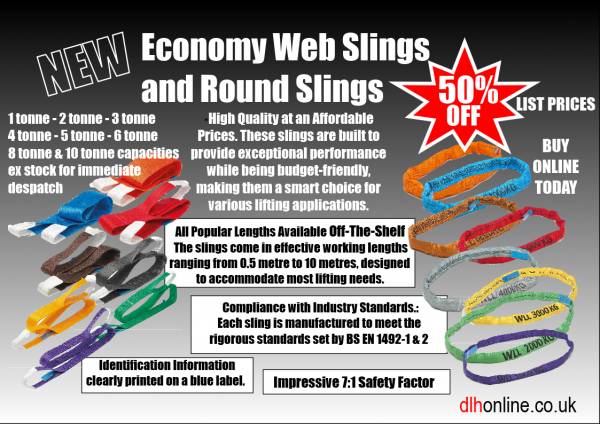

2025 Featured Products - New Economy Polyester Web and Round Slings

A new economy range of polyester web slings and polyester round slings is now available for immediate despatch, with a 50% discount on list prices. However, the only cut is the price – Quality is not an issue as all slings are of the highest tenacity and meet BS EN 1492 1 & 2 international standards. Economy Polyester Duplex (Two-Layer...Continue reading -

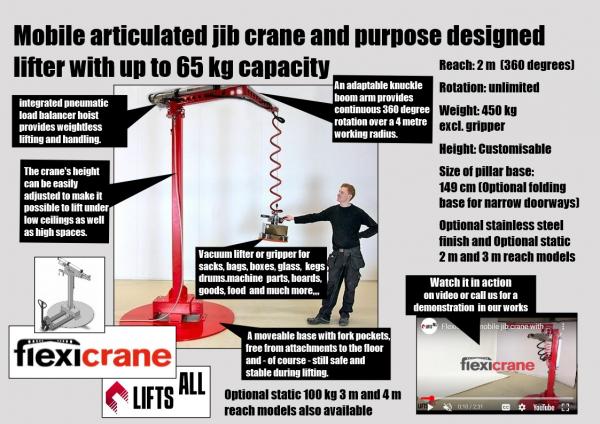

Product feature 2025 - Need product handling in different locations? The Flexicrane is ready for action.

If you need to use a jib crane in different areas in your workplace, The FlexiCrane Mobile is what you are looking for. The crane features forklift pockets, making it ideal for facilities that require flexible workflows and modular workstations. It is a lightweight and easy-to-use jib crane that can be moved around with a forklift or pallet truck. Combined...Continue reading -

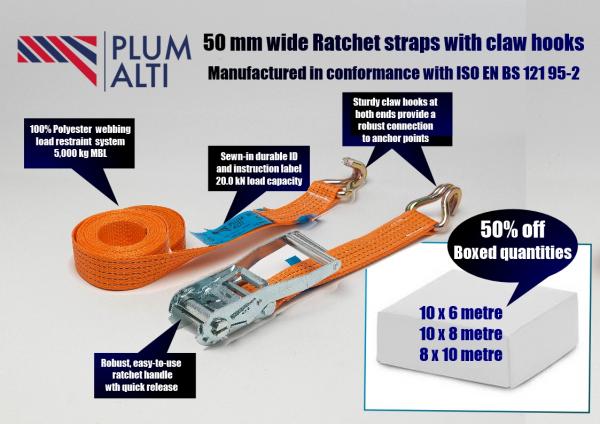

2025 Featured Product - Ratchet Straps

50 mm wide Ratchet straps (100% Polyester webbing) with claw hooks. Manufactured in conformance with ISO EN BS 121 95-2 2001, this High-quality load restraint system with high-strength webbing combined with a robust, easy-to-use ratchet handle and strong claw hooks. Available ex-stock for immediate despatch in 3 popular lengths – 6 metre, 8 metre and 10 metre. Save money by...Continue reading -

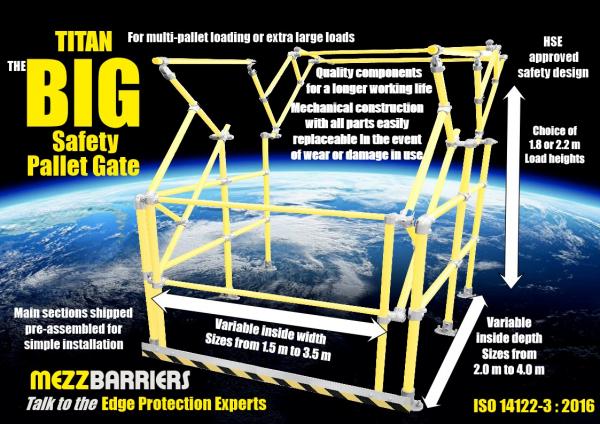

2025 Featured Product - Titan - The BIG Safety Pallet Gate

The Titan Extra Large Pallet Gate model is a truly versatile design with a balanced action that can be readily adapted for standard or non-standard extra-large loads or multi-pallet loading applications. Titan – the BIG Safety Pallet Gate - Features and Benefits: Conforms to BS EN ISO 14122-3:2016 Handrails and Mezzanine Gates – HSE-approved design Variable inside width from 1.5...Continue reading -

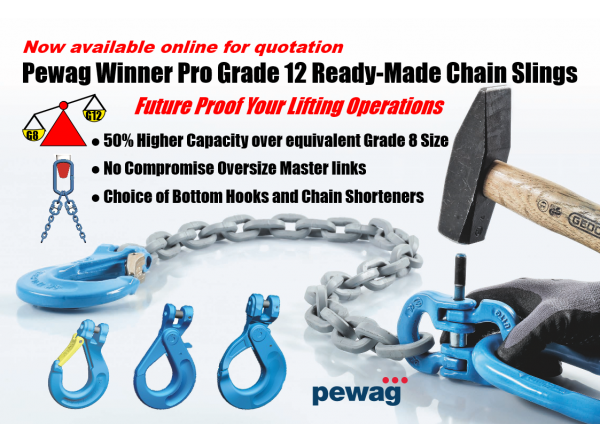

Future Proof Your Lifting Tackle

It's not exactly brand new in the lifting gear universe, but the grade 12 chain is now proving to be the future of chain sling systems, with major crane companies re-equipping their mobile cranes with significantly lighter slings. Are you ready to change? Grade 12 Winner Pro Chain Thanks to the intelligent use of material, the same cross-section achieves a...Continue reading -

Europa Engineering acquires Dale & Co.

Europa Engineering has acquired Dale & Co. (Lifting & Handling Specialists), founded in 1830, in Manchester. “This is a huge milestone for me, being my first acquisition, and I would like to thank Jacqueline and Martin, the previous owners of Dale & Co., for allowing us to be trusted as the new custodians of the business,” said Ella Cheetham, MD...Continue reading -

WHY INVESTING IN THE BEST MANUAL HANDLING TOOLS NOW CAN SAVE YOU MONEY IN THE LONGER TERM

Running a successful company is hard work, and one key aspect is ensuring the well-being of your employees. Making manual handling easier benefits your business and boosts morale among your staff MAKING THE RIGHT CHOICE However, finding an ideal solution should not start by trying to save on costs with the lowest price, as cheap answers inevitably do not turn...Continue reading