Lifts All Vacuum Sack Lifters - Lifts All - By Brand

Lifts All Vacuum Sack Lifters

Key Features

- Quick and smooth lifting of paper and plastic sacks

- Safety anti-drop off device is fitted

- Powered by compressed air and only requires a few per cent of the energy needed by traditional vacuum lifters

- Available in standard or stainless steel finish for vertical lift and lift/tilt applications.

- Request an evaluation for your project today!

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

The quick and smooth lifting of paper and plastic sacks with an easy to use pro speed-handle.operation. These Sack-Handlers optimize the frequent handling of sacks. For example: in the food, chemical, and pharmaceutical industries. Allows the operator to quickly and smoothly move sacks from and to a pallet to a conveyor belt or hopper. Available in standard or stainless steel finish for vertical lift and lift/tilt suction cu[ applications.

GENERAL DATA

- Maximum load: 50 kg

- Control: proportional control (PSH) / balancing

- Dead weight: 13.5 kg

- Media: 6-7 bar

- Article sack lifting of PSH: 92-10006

- Article sack lift with balancing: 92-100

- Bespoke solutions are also offered as standard.

Safety emergency lowering feature

For high air volume sack handling applications a safety anti-drop off device is fitted for air outage controlled lowering.

Complete Solutions

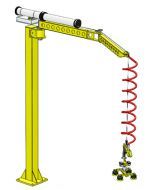

Usually supplied complete with a lightweight aluminium overhead crane system, fixed or mobile articulated swing jib for a complete handling solution. Alternatively, they can often be utilized with an existing system. Talk to our design team to find the perfect setup for your application.

To download our Sack Lifting Brochure Click Here

Watch it in action

Ergonomics in focus

Whereas manual handling is uncomfortable and prone to injuries, and traditional tube lifters ungainly, These Sack-Handlera are the perfect alternative. The ergonomic design immediately improves the productivity and the operator will quickly notice an improvement personal health. The employer will see a rapid decline in absence due backs and shoulders injuries.

BIG SAVINGS IN ENERGY COSTS

The handler pneumatically driven and only requires a few per cent of the energy needed by traditional vacuum lifters. This leads to beneficial effects on both economy and environment, as well as making the lifter silent.

Smarter Air Consumption - Unlike traditional vacuum lifters the Lifts All lifter knows when to switch on and off. The clever auto start turns on as soon as the vacuum cup lands on a surface. If the surface is air tight it immediately stops consuming air, even during the lift. It will only consume precisely as much air as it needs to keep a decent vacuum level.

And the biggest difference:

No waste of energy when the gripper is not carrying any load or when it is not in use.

Energy Saving is Standard

The energy saving system is standard and always included in the basic package. Ask us for an energy savings calculation for your company!

Want to find out more?

Complete our simple form above and we will get back to you to discuss your requirements in more detail or contact our project design engineer on 0161 223 1990 or by email to sales@dale-lifting.co.uk for a no-obligation quotation on the most cost effective solution for your application.