Crosby L320AN Alloy Eye Hook With Latch - 1.25t to 31.5t WLL - Lifting Hooks - Lifting Hoisting & Winching

Crosby L320AN Alloy Eye Hook With Latch - 1.25t to 31.5t WLL

Key Features

- Alloy eye hooks 1 tonne through 22 ton-average straightening load (ultimate load) is 5 times Working Load Limi

- Eye hooks are load rated.

- New integrated latch (S-4320) meets the World class standard for lifting.

- Deformation Indicators

- Angle Indicators

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

All Crosby 320 Eye Hoist Hooks incorporate the following features:

- A complete line of Eye hoist hooks.

- Available in carbon steel and alloy steel.

- Designed with a 5:1 Design Factor for (Carbon Steel); 4:1 Design Factor for (Alloy Steel).

- Eye hooks are load rated.

- Proper design, careful forging and precision controlled quenched and tempering gives maximum strength without excessive weight and bulk.

- Every Crosby Eye Hook has a pre-drilled cam which is equipped with a latch. Even years after the purchase of the original hook, replacement latch assemblies can be added. (Contact us)

- Chemical analysis and tensile tests performed on each PIC to verify chemistry and mechanical properties.

- Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

- Hoist hooks incorporate two types of strategically placed markings forged into the product which addresses two (2) QUIC-CHECK® features:

- Deformation Indicators and Angle Indicators (

- Metric Rated at 5:1 Design Factor for (Carbon Steel); 4:1 Design Factor for (Alloy Steel).

- Can be proof tested to 2 times the working Load Limit.

- Low profile hook tip.

- New integrated latch (S-4320) meets the World class standard for lifting.

- Heavy duty stamped latch interlocks with the hook tip.

- High cycle, long life spring.

- When secured with the proper cotter pin through the hole in the tip of the hook, meets the intent of OSHA Rule 1926.1431(g) and 1926.1501(g) for personnel hoisting.

- Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles.

| Working Load Limit (t) |

Hook ID Code |

Eye Hook Stock No. |

Weight Each (kg.) |

| Alloy |

Alloy S-320A S-320AN S.C. |

||

| 1.25 | †D | 1022375 | .28 |

| 1.6 | †F | 1022386 | .40 |

| 2.5 | †G | 1022397 | .65 |

| 3.2 | †H | 1022406 | .94 |

| 5.4 | †I | 1022419 | 1.95 |

| 8 | †J | 1022430 | 3.76 |

| 11.5 | †K | 1022441 | 6.80 |

| 16 | †L | 1022452 | 9.42 |

| 22 | †N | 1022465 | 17.9 |

| 31.5 | O | 1023546 | 27.2 |

† New 320N style hook.

- Hoist hooks incorporate markings forged into the product which addresses two (2) QUIC-CHECK® features.

- Deformation Indicators -- Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUIC-CHECK® measurement to determine if the throat opening has changed, thus indicating abuse or overload. To check, use a measuring device (i.e. tape measure) to measure the distance between the marks. The marks should align to either an inch or half-inch increment on the measuring device. If the measurement does not meet this criteria, the hook should be inspected further for possible damage.

- Angle Indicators -- Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two sling legs.

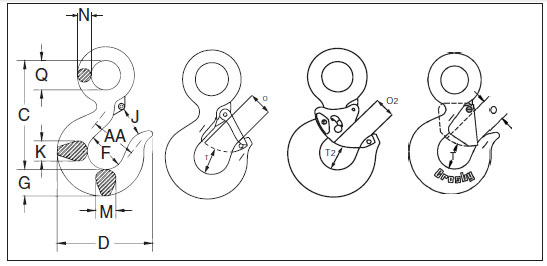

| Hook ID Code* |

Dimensions (mm) |

|||||||||||

| C | D | F | G | J | K | M | N | O † | Q | T † | AA | |

| D | 85.0 | 72.0 | 31.8 | 18.5 | 22.9 | 16.0 | 16.0 | 9.14 | 22.6 | 19.1 | 22.1 | 38.1 |

| F | 97.0 | 79.0 | 35.1 | 21.3 | 23.6 | 18.0 | 18.0 | 10.7 | 23.1 | 23.1 | 24.9 | 50.8 |

| G | 105 | 89.5 | 38.1 | 25.4 | 25.4 | 22.4 | 22.4 | 14.0 | 25.4 | 28.7 | 26.2 | 50.8 |

| H | 119 | 101 | 41.4 | 28.7 | 28.7 | 23.9 | 23.8 | 14.7 | 27.7 | 31.8 | 29.5 | 50.8 |

| I | 147 | 122 | 51.0 | 36.6 | 37.3 | 33.3 | 33.3 | 18.3 | 34.5 | 39.6 | 38.9 | 63.5 |

| J | 187 | 159 | 63.5 | 46.0 | 44.5 | 42.2 | 42.2 | 22.9 | 40.9 | 51.0 | 49.8 | 76.2 |

| K | 230 | 189 | 76.0 | 57.0 | 58.0 | 47.8 | 41.4 | 28.2 | 53.0 | 62.0 | 62.5 | 102 |

| L | 256 | 211 | 82.5 | 66.0 | 63.5 | 55.5 | 49.3 | 32.3 | 57.5 | 72.0 | 66.5 | 102 |

| N | 318 | 262 | 108 | 76.0 | 84.0 | 68.5 | 60.5 | 39.6 | 76.5 | 89.0 | 72.0 | 127 |

| O | 357 | 346 | 127 | 92.0 | 102 | 76.0 | 76.2 | 44.5 | 82.5 | 89.0 | 87.5 | 165 |

*Eye Hooks to 22TA), Proof load is 2 times Working Load Limit. Alloy eye hooks 1t through 22t - average straightening load (ultimate load) is 5 times Working Load Limit. Alloy eye hooks 30t through 60t - average straightening load (ultimate load) is 4.5 times Working Load Limit.

† to 22tA dimensions shown are for S-4320 Latch Kits.