Omega Space Saving Pallet Gate - Mezzbarriers - By Brand

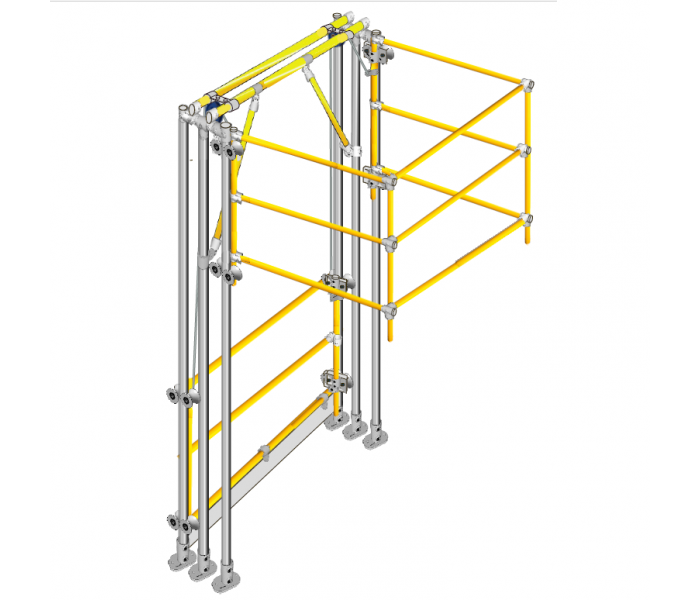

Omega Space Saving Pallet Gate

Custom-built product - Generally three weeks despatch - request a quote

Key Features

- Conforms to HSE and BS EN ISO 14122-3 : 2016

- All Galvanised finish or with Safety Yellow thermoplastic tube coated gates

- Easy to install and simple to use - Instructions provided

- Ideal for small areas or narrow walkways where space is tight

- All round pallet access - All parts are replaceable - CE marked

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

Omega Space Saving Pallet Gate

Solves this problem: How to provide an economic safety gate for high-level pallet loading where space is at a premium or the area is used for a walkway. or where all-round access to the pallet is required. Loads can be accessed on three sides. And, when in use, it protects people from coming into contact with moving loads and falls from the unprotected edge during fork truck loading access to the mezzanine floor.

An updated version of a standard design with improved rollers for ease of operation. Now constructed completely with our proven tube clamps system (No welded parts). This means that all parts are replaceable and it can be made to measure for pallets or loads up to 2.5metres high and up to 3000 mm inside width.

Conforms to BS EN ISO 14122-3:2016 Mezzanine Gates

The Omega model is offered to bespoke requirements - Use quote request form

- Up to 3000 mm inside width

- Up to 2000 mm inside depth

- Up to 2500 mm load height

- Intermediate widths to suit existing gap and lower height to suit headroom restriction

- All galvanised or Galvanised frames with safety yellow thermoplastic coated tubes for the gates.

Optional Extras - Use the quote request form

- Additional handrail to complete barrier infill or extend around your platform as required. (Attach a sketch showing dimensions)

- Floor plate in aluminium chequer plate 1250 mm wide x 1150 mm deep with 100mm fold to protect edge (Recommended for wood floors). Order 2 for wider coverage). Delivery free when ordered with your Omega pallet gate

- A safety net in the edge gate

- Hi-Vis Hazard warning Yellow/Black tube sleeves 1000 mm lengths - Easy to fit and cut to length (Sold separately)

Why use this safety gate system?

The Omega pallet gate design has proven to be the ideal answer to pallet loading issues. Particularly, the space-saving side frames with free-rolling rollers make raising and lowering effortless.

Replaces swing gates, removable bars or chains which can be left open.

The innovative Omega safety gates have been specifically re-developed to provide fool-proof safety for personnel working a height. The design is ideal for many loading applications, from standard pallets to exceptionally large loads on mezzanine floors, loading docks, and high-level platforms.

How It Works

The gates are mounted between the space-saving side frames and have nylon rollers with bearings operated by wire rope pulleys mounted at top of the side frames.

Omega Space-Saving Safety Gate System - for standard pallets or special versions for specific applications are possible.

Features and benefits:

- All Galvanised Tubular steel construction or Galvanised with Yellow Thermoplastic (Warm Touch) Coated Gate cross tubes

- 100 mm high Aluminium kick plate attached to the bottom edge gate

- Pull down/Push up action for easy operation of the balanced gates

- Supplied ready for simple installation (Partially dismantled for shipment)

- High load clearance

- Clear of floor edge when open or shut

- All parts are replaceable

- Separates people from moving loads and falling from the unprotected edge

- Allows a clear view of the operation

- Reinforces a sense of security

- Fail-safe operation

| Frequently asked questions for pallet gates |

|---|

Component Specification

Mezzbarriers tube clamps are made of malleable cast iron. Manufactured in conformance with BS EN 1562:1997, a dependable and well-proven material for this type of product. The fittings are then hot-dipped galvanised to BS EN ISO 1461:1999 to produce a durable corrosion-resistant finished surface for extended life. Grub screws are stainless steel. Nylon rollers are self-lubricating (low coefficient of friction), excellent wear and abrasion resistance with noise reduction and high Impact strength