CROSBY HR1000M - HEAVY LIFT SWIVEL HOIST RING - METRIC - Crosby - By Brand

CROSBY HR1000M - HEAVY LIFT SWIVEL HOIST RING - METRIC

Key Features

- Capacity range from 500 kg to 13,750 kg

- Thread range M8 to M38

- Larger opening than standard Hoist Ring bail.

- The Working Load Limit and Recommended Torque value are permanently stamped into each washer.

- Individually Proof Tested to 2-1/2 times Working Load Limit.

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

CROSBY HR1000M - HEAVY LIFT SWIVEL HOIST RING - METRIC

Forged bail provides the following:

• Easily readable “Raised Lettering” showing the name Crosby or “CG” and PIC Code for material traceability.

• Greater durability providing the increased “Toughness” desired in potentially abusive field conditions.

• Larger opening than standard Hoist Ring bail.

• Top washer is colour coded for easy identification (Red for UNC threads and Silver for Metric threads)

• The Working Load Limit and Recommended Torque value are permanently stamped into each washer.

• Individually Proof Tested to 2-1/2 times Working Load Limit.

• Available in both UNC Thread and Metric Thread style.

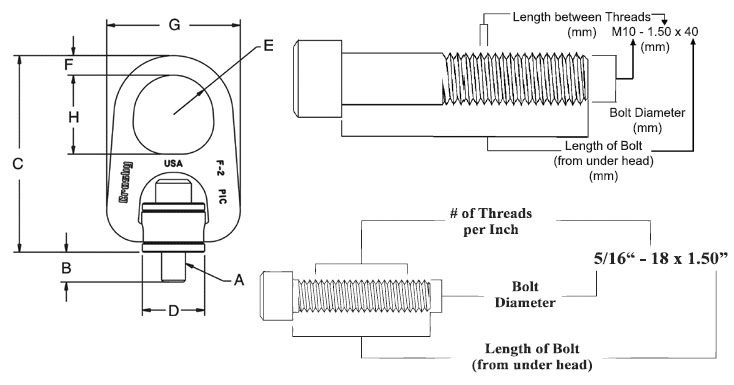

• BOLT SIZE IDENTIFICATION: The size of the bolt will be stated as in the drawing below. The illustration shows the meaning of each dimension given.

• Frame 2 and larger are RFID EQUIPPED.

| Frame Size No. |

HR-1000M Stock No. |

Working Load Limit (kg)* | Torque in Nm |

Dimensions (mm) | Weight Each (kg.) |

||||||||

| At a 5:1 Design Factor*** |

At a 4:1 Design Factor *** |

Bolt Size A ‡ ‡ |

Eff. Thread Projection Length B |

C |

D |

Radius E |

Diameter F |

G |

H |

||||

| 1 | 1068307 | 400 | 500 | 10 | M8 x 1.25 x 40 | 15.2 | 93.7 | 24.6 | 15.7 | 11.2 | 57.7 | 35.1 | .3 |

| 1 | 1068316 | 450 | 550 | 16 | M10 x 1.50 x 40 | 15.2 | 93.7 | 24.6 | 15.7 | 11.2 | 57.7 | 35.1 | .3 |

| 2 | 1068325 | 1050 | 1300 | 38 | M12 x 1.75 x 55 | 15.5 | 162 | 49.8 | 31.8 | 19.1 | 107 | 63.5 | 1.5 |

| 2 | 1068334 | 1900 | 2400 | 81 | M16 x 2.00 x 65 | 25.5 | 162 | 49.8 | 31.8 | 19.1 | 107 | 63.5 | 1.5 |

| 2 | 1068343 | 2150 | 2700 | 136 | M20 x 2.50 x 70 | 30.5 | 162 | 49.8 | 31.8 | 19.1 | 107 | 63.5 | 1.6 |

| 3 | 1068352 | 3000 | 3750 | 136 | M20 x 2.50 x 80 | 25.4 | 220 | 75.2 | 41.4 | 25.4 | 159 | 82.6 | 4.6 |

| 3 | 1068361 | 4200 | 5250 | 312 | M24 x 3.00 x 90 | 35.4 | 220 | 75.2 | 41.4 | 25.4 | 159 | 82.6 | 4.8 |

| 4 | 1068370 | 7000 | 8750 | 637 | M30 x 3.50 x 140 | 66.2 | 285 | 94.2 | 50.8 | 31.8 | 199 | 102 | 9.7 |

| 4 | 1068389 | 11000 | 13750 | 1005 | M36 x 4.00 x 130 | 56.2 | 285 | 94.2 | 50.8 | 31.8 | 199 | 102 | 10.2 |

*Ultimate Load is 5 times the Working Load Limit.

** Ultimate Load is 4.5 times the Working Load Limit for 7000# Hoist Ring when tested in 90 degree orientation.

*** Individually proof loaded to 2-1/2 times the Working Load Limit based on the 4:1 design factor.

† Long Bolts are designed to be used with soft metal (i.e., aluminum) work piece. While the long bolts may also be used with ferrous metal

(i.e.,steel & iron) work piece, short bolts are designed for ferrous work pieces only.

‡ Bolt specification is a Grade 8 Alloy socket head cap screw to ASTM A 574. ‡‡ Bolt specification is a Grade 12.9 Alloy socket head cap screw to DIN 912.

NOTE: The tightening torque values shown are based upon threads being clean, dry and free of lubrication.