CROSBY HR125 - SWIVEL HOIST RING - UNC - Crosby - By Brand

CROSBY HR125 - SWIVEL HOIST RING - UNC

Key Features

- UNC threads available in sizes from 800 pounds to 100,000 pounds Working Load Limit, with a design factor of 5 to 1.

- Thread range from 5/16" to 3.1/2" UNC

- All Components are Alloy Steel - Quenched and Tempered.

- Rated at 100% at 90° angle.

- 100% individually proof tested to 2-1/2 times the Working Load Limit with certification and Statistically Magnetic Particle inspected.

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

CROSBY HR125 - SWIVEL HOIST RING - UNC

- UNC threads available in sizes from 800 pounds to 100,000 pounds Working Load Limit, with a design factor of 5 to 1.

- All Components are Alloy Steel - Quenched and Tempered.

- Rated at 100% at 90° angle.

- 100% individually proof tested to 2-1/2 times the Working Load Limit with certification and Statistically Magnetic Particle inspected. (Can be furnished 100% Magnetic Particle inspected when requested at time of order.)

- Each product has a Product Identification Code (PIC) for material traceability along with a Working Load Limit and the name Crosby or “CG” stamped into it.

- Meets or exceeds all the requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these hoist rings meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

- 360° swivel and 180° pivot action.

- Fatigue rated to 20,000 cycles at 1-1/2 times the Working Load Limit.

- Individually packaged along with proper application instructions and warning information.

- Bolt is secured with E-clip, threads are grooved. This method allows for easy disassembly and assembly of hoist ring for thorough examination of all components. Replacement kits are available.

- Bolts are individually Proof Tested.

- Multiple Bolt length available to meet specific application requirements.

- Zinc Plated (Yellow Chromate) finish for increased corrosion protection thru 30,000 pounds size.

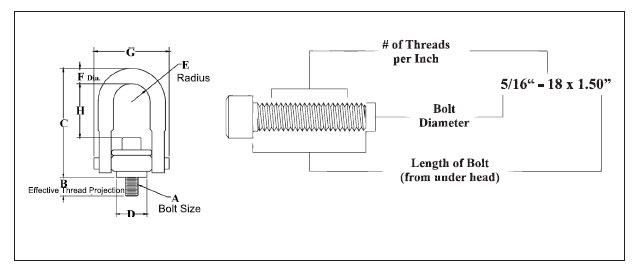

| Frame Size No. |

HR-125 Stock No. |

Working Load Limit (lbs.)* |

Torque in Ft. Lbs. |

Bolt Size A ‡ (in.) |

Dimensions (mm) |

Weight Each (kg.) |

||||||

| Effective Thread Projection Length B |

C |

D |

Radius E |

Diameter F |

G |

H |

||||||

| 1 † | 1016887 | 800 | 7 | 5/16 - 18 x 1.50 | 14.7 | 69.1 | 24.6 | 11.7 | 8.60 | 47.5 | 28.4 | .17 |

| 1 † | 1016898 | 1000 | 12 | 3/8 - 16 x 1.50 | 14.7 | 69.1 | 24.6 | 11.7 | 8.60 | 47.5 | 26.7 | .18 |

| 2 | 1016909 | 2500 | 28 | 1/2 - 13 x 2.00 | 17.8 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 58.2 | 1.06 |

| 2 † | 1016912 | 2500 | 28 | 1/2 - 13 x 2.50 | 30.5 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 58.2 | 1.07 |

| 2 | 1016920 | 4000 | 60 | 5/8 - 11 x 2.00 | 17.8 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 54.9 | 1.09 |

| 2 † | 1016924 | 4000 | 60 | 5/8 - 11 x 2.75 | 36.8 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 54.9 | 1.12 |

| 2 | 1016931 | 5000 | 100 | 3/4 - 10 x 2.25 | 24.1 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 51.8 | 1.14 |

| 2 † | 1016935 | 5000 | 100 | 3/4 - 10 x 2.75 | 36.8 | 123 | 49.8 | 22.1 | 17.5 | 85.1 | 51.8 | 1.17 |

| 3 | 1016942 | 7000 ** | 100 | 3/4 - 10 x 2.75 | 22.6 | 167 | 75.2 | 34.5 | 23.9 | 124 | 75.4 | 3.05 |

| 3 † | 1016946 | 7000 ** | 100 | 3/4 - 10 x 3.50 | 41.7 | 167 | 75.2 | 34.5 | 23.9 | 124 | 75.4 | 3.09 |

| 3 | 1016953 | 8000 | 160 | 7/8 - 9 x 2.75 | 22.6 | 167 | 75.2 | 34.5 | 23.9 | 124 | 72.1 | 3.10 |

| 3 † | 1016957 | 8000 | 160 | 7/8 - 9 x 3.50 | 41.7 | 167 | 75.2 | 34.5 | 23.9 | 124 | 72.1 | 3.16 |

| 3 | 1016964 | 10000 | 230 | 1 - 8 x 3.00 | 29.0 | 167 | 75.2 | 34.5 | 23.9 | 124 | 69.1 | 3.22 |

| 3 † | 1016969 | 10000 | 230 | 1 - 8 x 4.00 | 54.4 | 167 | 75.2 | 34.5 | 23.9 | 124 | 69.1 | 3.32 |

| 4 | 1016975 | 15000 | 470 | 1-1/4 - 7 x 4.50 | 56.1 | 221 | 94.2 | 44.5 | 30.2 | 157 | 99.8 | 6.58 |

| 5 | 1016986 | 24000 | 800 | 1-1/2 - 6 x 6.50 | 69.3 | 315 | 120 | 60.7 | 44.5 | 215 | 143 | 17.1 |

| 5 | 1016997 | 30000 | 1100 | 2 - 4-1/2 x 6.50 | 69.3 | 315 | 120 | 60.7 | 44.5 | 215 | 131 | 18.5 |

| 6 | 1017001 | 50000 | 2100 | 2-1/2 - 4 x 8.0 | 102 | 429 | 146 | 76.2 | 57.2 | 279 | 204 | 39.9 |

| 7 | 1017005 | 75000 | 4300 | 3 - 4 x 10.5 | 127 | 495 | 184 | 95.3 | 69.9 | 360 | 216 | 75.3 |

| 8 | 1017009 | 100000 | 5100 | 3-1/2 - 4 x 13.0 # | 178 | 561 | 197 | 102 | 82.6 | 404 | 236 | 120 |

- Individually Proof Tested to 2-1/2 times Working Load Limit.

- Bolt specification is a Grade 8 Alloy socket head cap screw to ASTM A 574. All threads listed are UNC. Illustration shows meaning of each dimension given.

- BOLT SIZE IDENTIFICATION: The size of the bolt will be stated as in the drawing

- † Frame 2 and larger are RFID EQUIPPED.

Top washer has the following features:

- The Working Load Limit and Recommended Torque value are permanently stamped into each washer.

- Washer is color coded for easy identification: Red - UNC thread