Yale TPM Permanent Lifting Magnets - Yale - By Brand

Yale TPM Permanent Lifting Magnets

Key Features

- 7 sizes 100 kg to 3,000 kg capacities

- Compact design of the units for a large number of applications

- The load is not affected mechanically which allows lifting of flat as well as round material

- The permanent magnets do not require electric energy and will leave only minor residual magnetism on the the material after use.

- The magnets are activated/deactivated easily by turning a locking lever

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

TPM permanent lifting magnets are ideal tools for easy, quick and economical transport of heavy objects

The compact design of the units for a large number of applications. The load is not affected mechanically, allowing the lifting of flat and round material. The efficient magnet body provides a strong lifting capacity at a low dead weight.

The permanent magnets do not require electric energy and will leave only minor residual magnetism on the

The magnets are activated/deactivated easily by turning a locking lever. In inactivated conditions, the hand lever will

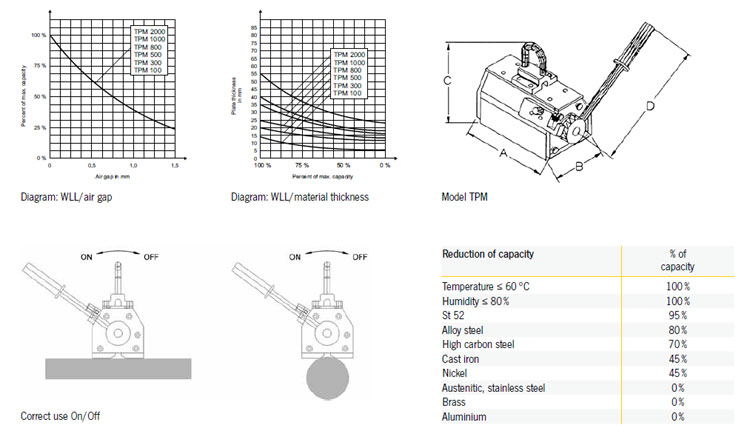

the contact surfaces. Air gaps occur in a number of different ways such as paint, dust and heavy mill scale. Poorly machined surfaces also constitute an air gap. Please down rate the magnet capacity in accordance with the adhesive force/air gap diagram below.

Typical values:

| Model | Flat material | Round material | Weight kg |

Tear off force kg |

Dimensions | ||||||||

| Article No. | Maximum capacity WLL kg** |

Minimum thickness to obtain max. WLL mm** |

Maximum length of material mm |

Maximum capacity WLL kg** |

Diameter mm |

Maximum length of material mm |

A mm |

B mm |

C mm |

D mm |

|||

| TPM 0.1 |

N56400001 |

100 |

14 | 2000 | 50 | 40-300 | 2000 | 5.3 | 300 | 122 | 69 | 185 | 160 |

|

TPM 0.3 |

N56400002 | 300 | 20 | 2500 | 150 | 60-300 | 2500 | 13.5 | 900 | 192 | 95 | 225 | 250 |

| TPM 0.5 | N56400003 | 500 | 24 | 3000 | 250 |

60-400 |

3000 |

27.5 | 1500 | 232 | 120 | 270 | 250 |

|

TPM 0.8 |

N56400004 | 800 | 34 | 3500 | 400 | 60-400 | 3500 | 52 | 2400 | 302 | 154 | 320 | 450 |

|

TPM 1.0 |

N56400004 | 1000 | 40 | 3500 | 500 | 80-400 | 3500 | 57 | 3000 | 332 | 154 | 320 | 450 |

| TPM 2.0 |

N56400005 |

2000 |

55 | 3500 | 1000 | 100-400 | 3500 | 125 | 6000 | 392 | 196 | 420 | 450 |

| TPM 3.0 |

N56400006 |

3000 |

56.5 | 3500 | 1500 | 200-500 | 3500 | 195 | 9000 | 497 | 220 | 453 | 600 |

corrosion, paint etc. Maximum lifting capacity is achieved by using mild steels with the noted minimum thickness. *

Measured on bright drawn material S 235 JR (ST 37), air gap < 0,1 mm