Sack tipping stations are designed to provide safe handling for all types of sacks and boxes while controlling and reducing dust emissions. All well and good, but what about getting the sacks safely to the tip station?

The sack stations are ergonomically designed to ensure the safe handling of the sacks and boxes, and they come with integrated aspirators and filters to reduce emissions and exposure. However, sack lifting is an essential aspect of the operation in many industries, including agriculture, construction, food, pharmaceuticals, and manufacturing. It is essential to ensure that sacks are handled safely and efficiently to prevent injuries and damage to the products.

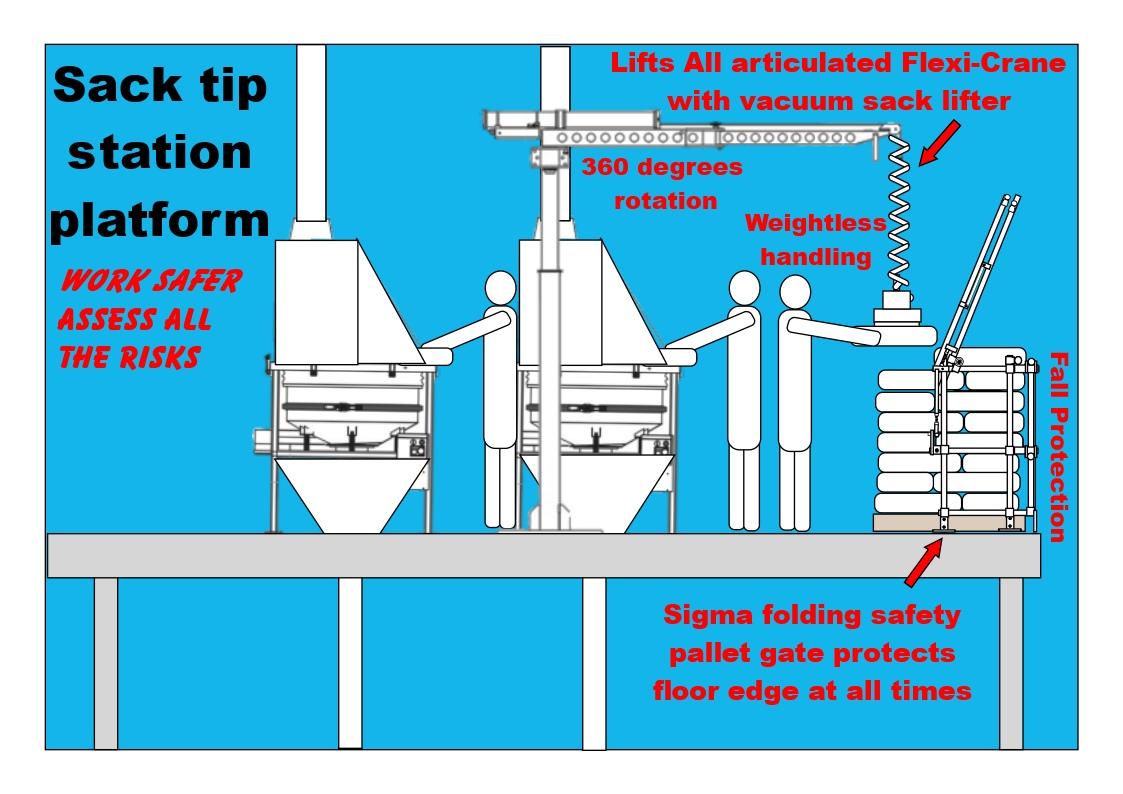

And, where the sack tip station is located on a raised platform, the transfer of loaded sack pallets can present a fall hazard at unguarded loading points.

Managing the risk

- Identify which tasks present a serious risk of acute injury from heavy lifting, repetitive strain injuries and falls from height.

- Assess these tasks in detail to decide what factors lead to any risks.

- Introduce mechanisation where this is reasonably practicable, e.g. vacuum lifters, and safety pallet gates.

- Where possible, introduce measures to prevent injury, e.g. reduce weights of sacks/boxes to 25kg or below, improve ergonomic design of workstations and work areas, job rotation, training, medical surveillance, job transfer

- Consult fully with trade union safety representatives or other employee representatives and workers to ensure effective and workable solutions to problems.

Mechanical handling of sacks, bags, boxes etc.

Musculoskeletal injuries can arise from stacking/unstacking and filling/emptying containers (such as boxes, crates and sacks). A key task to which attention should be paid when carrying out risk assessments.

Vacuum bag lifters are perfectly suited for quick and effective bag and sack handling. They are integral for safety, playing a central role in the distribution of materials worldwide. As a packaging system, bags and sacks meet most basic logistic requirements. They portion, protect, transport, store and sell the products they hold. Careful handling is required to keep the product and the sack undamaged – The Lifts All pneumatic sack handling system offers quick and smooth lifting of paper and plastic sacks with an easy-to-use pro-speed-handle operation.

‘Lifts All’ Sack Handlers - Brochure

Lifts All Sack-Handlers optimise the frequent handling of sacks. The lifter lets the operator quickly and smoothly move sacks to and from a pallet or hopper. Available in standard or stainless-steel finish for vertical lift and lift/tilt suction cup applications

.Safety emergency lowering feature.

A safety anti-drop-off device is fitted for air outage-controlled lowering for high air volume sack handling applications.

Complete Solutions with Flexi-Crane - Brochure

The vacuum lifter can be supplied complete with Lifts All Flexi-Crane fixed or moveable swing jib for a complete handling solution. The versatile Flexi-Crane follows you wherever you go - easily, silently and endlessly rotating!

The Flexi-Crane can be fitted with a steel frame on the wall, floor, ceiling, or portable base (Move to the next location with a pallet truck or forklift) depending on your workplace needs. The height of the column is adjustable and can be adapted for installation directly into the workplace. There is always room for a Flexi Crane-lift system!

Thanks to the handy size and weight of the crane it can be easily and quickly installed at a low cost. The low weight combined with low friction in the lifting arm joints makes the Flexi-Crane very quiet and easy to work with.

Energy-efficient air hoist

Because the crane system is powered by compressed air, it can save money. It only requires a few per cent of the energy needed by traditional electrically powered vacuum tube lifters; the Lifts-All standby mode costs nothing!

Another advantage of Flexi-Crane is that, thanks to a clever design it can rotate 360 degrees, a full turn endlessly! And, with the Flexi-Crane's flexibility and responsiveness, it outperforms all comparable light-weight cranes, jib cranes. and articulated Jibs with ease.

Lifting aids for cleanroom environments

For cleanroom environments, the Flexi-Crane can be supplied completely in stainless steel. Combined with stainless steel lifting tools, we can thus provide most clean room classed workstations with ergonomic lifting aids. We can polish the crane and lifting equipment to the requested finish and deliver ATEX approval for the entire lift system.

Whether you are lifting bags, components, sacks, boxes, drums or boards there is generally a gripper tailor-made to suit your industry requirements.

Lifts-All Finish options:

- Lacquered: red (RAL 3020)

- Stainless steel - 304 Blast or highly polished

- Stainless steel 316 Blast or highly polished finishes

For more information – Request a quote or call our dedicated sales team on 0161 223 1990 or email sales@dale-lifting.co.uk

Platform Edge Fall Protection.

High-level platforms are commonly used for Sack tipping operations and there can be incidents where workers can injure themselves when working at unprotected high-level openings. The Health and Safety Executive (HSE) has urged all organisations to ensure their mezzanine floors or raised platforms have edge protection handrails and dual safety loading gates to prevent workers from falling.

Pallet Loading Safety Gates

Many high-level loading platforms have gaps in the handrail used as pallet loading areas with no safety barrier or just a swing gate, sliding (trombone) gate, or removable bars or chains. These are dangerous to operate or are routinely left open and are accidents waiting to happen!

When considering what type of safety gate is required. The generally accepted answer is an up-and-over safety pallet gate. However, these are of no use when the pallet has to be unloaded using a vacuum sack lifter.

The only solution is the purpose-designed Mezzbarriers Sigma universal safety pallet gate system. - Sigma Pallet Gate Brochure

What’s so special about the Sigma pallet gate?

- It conforms to BS EN ISO 14122-3:2016 for handrails and pallet gates.

- Dual gates protect the edge at all times – Open or closed.

- The edge gate does not protrude over the floor's edge. There are no overhead bars when open, with less risk of damage during the loading operation.

- Fitted with 100 mm high Aluminium kick plates to prevent items from falling from the edge.

- When the operator pulls down the inner gate, the mechanisms incorporated in the side frames automatically releases the integrated lock to allow the twin edge gates to pivot up to the vertical position on either side of the opening.

- When used with standard pallets, the side frames can be reduced in depth (Minimum 500 mm) to save space and allow good access to a pallet on three sides.

- The Sigma model can be used with a vacuum-handling crane for unloading bags, sacks, etc. The inner gate can be modified to rake forward in the folded-up position when shut. This allows the vacuum hoist to swing over the entire pallet to reach every sack, bag or box.

- The Sigma design allows for the production of a bespoke (Up to 3000 mm inside width) low-cost gate that can be easily adapted in height, width and depth and will be easy to assemble and adjust/maintain on-site to ensure optimum operation.

- The Sigma construction combines our tried and tested standard tube and mechanical component construction with specially designed pivot joints and tube rotators. All parts are replaceable in the event of damage in use.

Sigma Finish Options

- All galvanised (Kick plate aluminium)

- Safety yellow thermoplastic (Warm to touch) coated tube and galvanised components

- Optional Aluminium floor/edge protection plate 1250 mm wide x 1150 mm deep plus 100 mm fold down. 3 mm checker plate (Undrilled). Recommended for wooden floors. Buy two for wider gates.