Custom Pallet/Load Handling Safety Gate Design - Mezzbarriers - By Brand

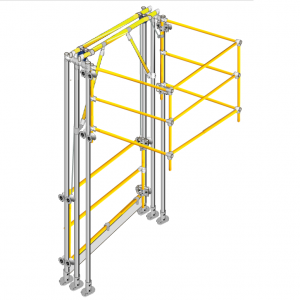

Custom Pallet/Load Handling Safety Gate Design

Click below to download our easy guide to specify your custom pallet gate and request a quote (E-form PDF)

Specify your custom pallet gate and request a quote |

Key Features

- Not sure which type of safety loading gate you need? - we're here to help!

- Customised designs to suit your exact requirements - Conformance with BS EN ISO 14122-3:2016.

- Use our online quote request form to tell us about your application, to obtain your no-obligation competitive quotation

- We supply safety loading gates for almost any application - Mezzanines, work platforms, high level openings and doorways.

- Expert advice is just a phone call away - 0161 223 1990

Delivery Information

Order online for delivery to Mainland UK VAT eligible locations only. Delivery charges will be shown in the shopping cart. Despatch dates for products can vary, if urgent, please contact us. Request a quote for postcodes DD, IV, KW, PA, AB, BT, HS, TR. PO30-PO42, southern Ireland, Channel Islands. For international destinations restrictions may apply.

Returns Policy

Simply email us at sales@dale-lifting.co.uk or call 0161 223 1990 and we will be able to give you a returns authorisation code, which must be sent with the returned item. Returns should be authorised within 14 days from the day of delivery to you. Items should be returned in unused condition & due to the nature of our products a restocking fee may apply. Unfortunately, delivery charges are not refundable. Items returned without an authorisation code may not be accepted. Normally All refunds will be processed within 7- 10 working days on receipt of returned goods.

Non-standard (Quote only, pre-order or custom-made products)

Custom made to order products are not covered by our returns policy. Please ensure when ordering all measurements and capacities are correct as we are unable to refund on these products.

For more information see https://www.dlhonline.co.uk/terms-conditions

Need a Custom Pallet Gate to your exact dimensions or special application?

There are numerous standard designs of pallet gates on the market; however, some of these devices may not be suitable for your specific application and location. You may consider a gate system designed to meet your needs. Guardrail openings and high-level doorways are constructed and function differently, a specific design of an all-around protection safety gate may be needed for your situation; one size does not fit all!

No Problem - Tell us where your safety pallet gate will be used.

Download our E-form PDF: Specify Your Pallet/Load Handling Gate and Request a no-obligation quotation

We make Safety Gates for:

- Loading by forklift to a mezzanine or platform

- Loading by hoist to a mezzanine, platform or opening

- Loading onto a balcony with an opening or doorway

- Loading through an opening or doorway

If you need more help? Call 0161 223 1990 to talk to an expert to guide you through the process, or email: mezzbarriers@dale-lifting.co.uk